From left: Dr Mathialagan, Ir Chan and Koay with students and staff

Prior to the talk delivered by Executive Deputy Chairman of Dialog Group Berhad Ir Chan Yew Kai, an award ceremony for the “Best Final Year Project in Petrochemical Engineering” was held on 13 March 2019 at UTAR Kampar Campus.

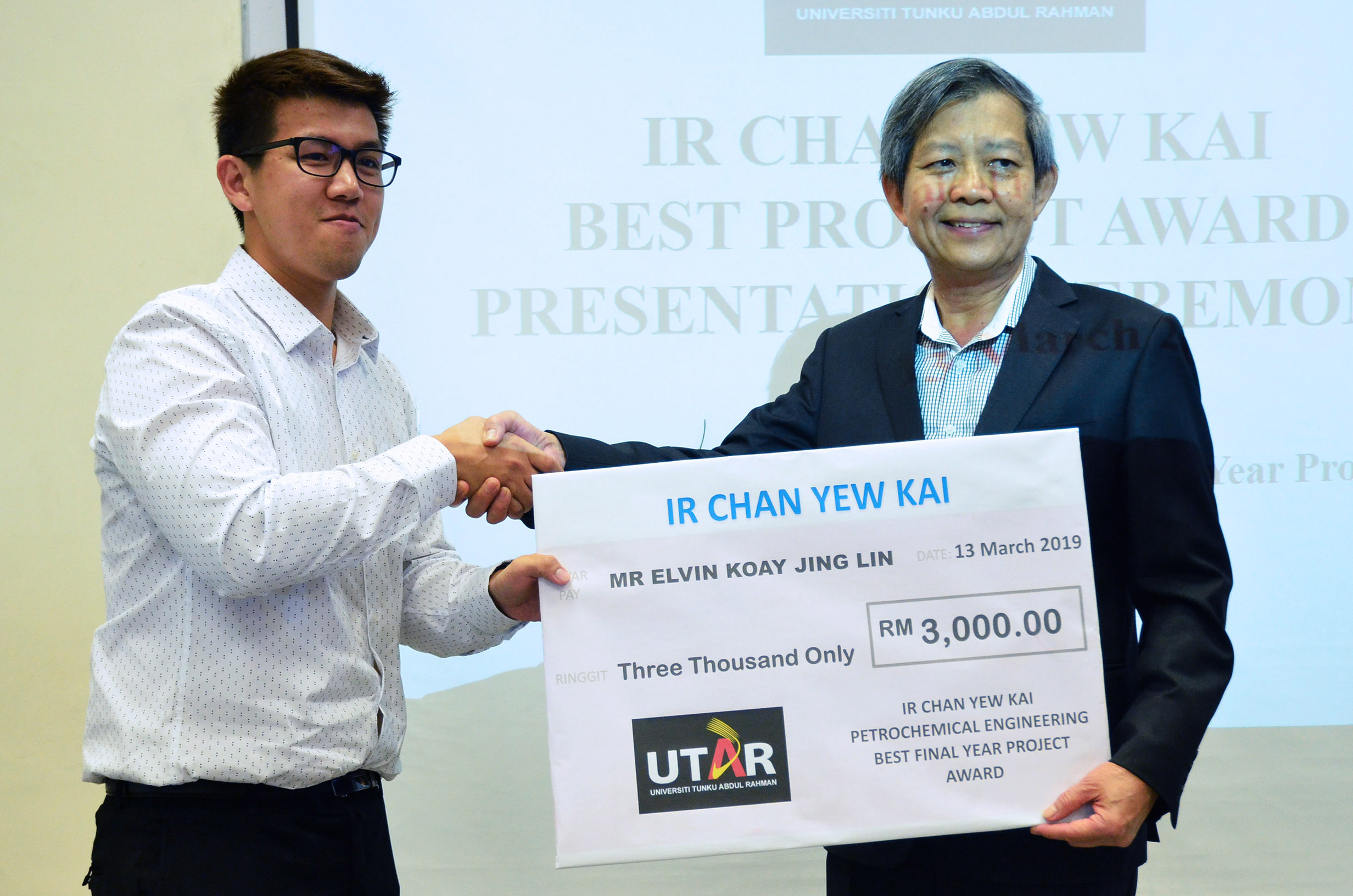

The award ceremony aimed to give recognition to students’ excellent research work. It saw Ir Chan presenting the award to Final Year Bachelor of Engineering (Hons) Petrochemical Engineering student Elvin Koay Jing Lin. Koay received a certificate and cash prize of RM3,000.

Also present at the award ceremony were Faculty of Engineering and Green Technology (FEGT) Deputy Dean for R&D and Postgraduate Programmes Dr Lo Po Kim, Deputy Dean for Student Development and Industrial Training Dr Tan Kok Tat, Department of PetroChemical Engineering Head Dr Mathialagan Muniyadi, staff and students.

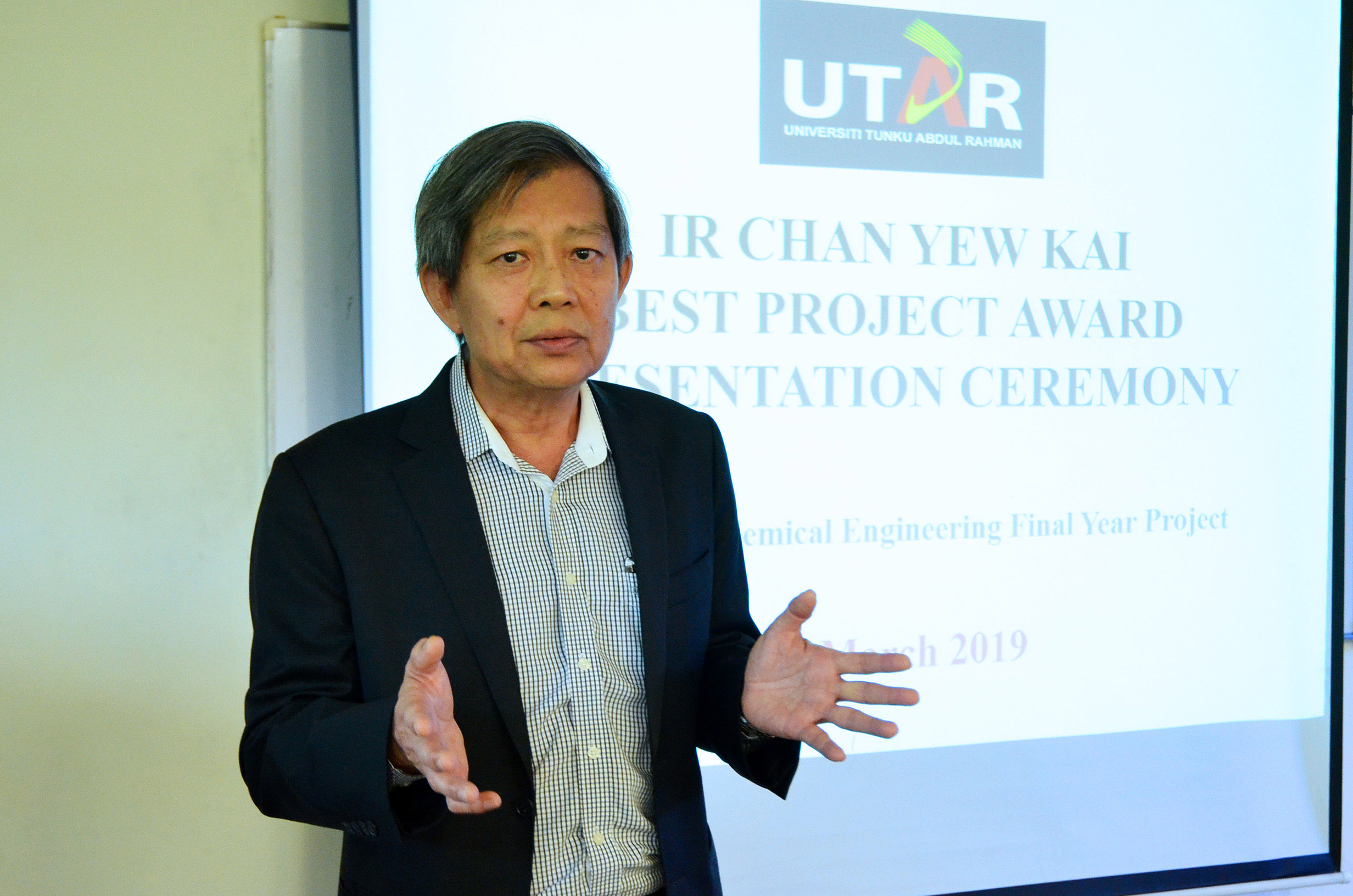

Ir Chan giving his speech

“I have always enjoyed attending student events, including this morning’s award ceremony. Looking at the students, I reminiscent my old days as a chemical engineer. Now that I have achieved my success, I want to be able to share my success and give back to society, including helping and giving guidance to students in this field. For this award, my selection is based on the research innovation and the impact of the research on society. I have received my researches from students and I noticed that the researches have improved. Therefore, I want to encourage all students here to have passion in whatever you do and be excellent in those tasks,” said Ir Chan in his speech.

Ir Chan (right) presenting the mock cheque to Koay

“I am very honoured to be given this award because it not only recognises my hard work but it also recognises my research contribution to the industry. Filtration membranes are common in the industry and all of which are providing excellent results. These current filtration membranes also provide good quality filtrate but there is no date on the rate of filtration. However, my research stood out from the point that I can maintain the quality of the filtrate at a certain level that is acceptable by the environmental standards, at the same time providing a high filtration rate. Unlike other filtration membranes which are made of fibres that are fragile, or ceramic membranes that are brittle; the material I used for my filtration membrane is rubber. Rubber membranes are flexible, can be stretched, and it is much more durable,” said Koay.

When asked of the motivation for conducting this research, Koay said, “I heard about this research from my supervisor Assoc Prof Dr Yamuna Munusamy. This research was interesting because I believed it was a research that can contribute much to the industry, potentially affect the cost of the industry, affect the quality of the output, and subsequently, the profit of the industry. Therefore, it was a research that was worth my effort and hard work.”

Koay’s research is titled “Latex Based Membrane for Oily Waste Water Filtration: Study on the Sulfur Concentration Effect”. The study aims to optimise the sulphur concentration for NBR/GO membranes bystudying the effects of sulphur concentration on water flux, oil rejection percentage aswell as tensile strength properties of the membrane. Graphene Oxide was preparedusing the conventional Hummer’s method where Graphene nanofibre was oxidisedinto Graphite Oxide and further sonicated to Graphene Oxide. NBR/GO membraneswere prepared using latex compounding method with variation in sulphur concentration and cured before being subjected to performance tests and analysis such as water fluxtest, oil rejection test, tensile test and scanning electron microscopy analysis. Theoutcome of this research confirms a 1.0pHr sulphur concentration is optimal inproviding a high water flux of 834.1𝐿/𝑚2ℎ𝑟 while still maintaining a high oil rejectionrate percentage of 92.23%. This is further supported by the SEM images where a highdegree of surface wrinkle is observed to facilitate water permeation. The tensile strength of the 1.0pHr sulphur sample is slightly weaker than the 1.5pHr sulphur samplebut the water flux and oil rejection recorded for the 1.5pHr sulfur sample issignificantly lower at 559.6𝐿/𝑚2ℎ𝑟 and 91.46%. This further justifies the choice of 1.0pHr sulphur concentration as the desired choice.

After the award ceremony, Ir Chan spoke about “Implementing a Process Safety Culture in the Engineering, Construction, and Maintenance Environment”. He began with an introduction about Dialog Group Berhad and listed the core services of the company. The core services included logistics assets and services – tank terminal and supply base; upstream assets and services; engineering procurement, construction and commissioning; specialist products and services; plant maintenance and catalyst handling services; fabrication; and ePayment technology solutions.

Ir Chan explaining one of the chemical disaster cases

On process safety, Ir Chan explained that it is the prevention of unintentional releases of chemicals, energy and other potentially dangerous materials, during the course of chemical processes that can have a serious effect on plants and environment. To illustrate better, he shared examples of chemical disasters that had taken place globally. The first case Ir Chan spoke about was the Bhopal Methyl Isocyanate Disaster, which happened in December 1984. It was also known as the world’s worst chemical industry disaster. According to Ir Chan, the incident happened because of 30 MT of Methyl Isocyanate leaked into the atmosphere after water ingress into a tank, which caused runaway exothermic reaction. The water ingress resulted from backflow of water when routine pipe maintenance was carried out. The incident caused 15,000 fatalities.

Another example shared was the Piper Alpha Oil Rig Disaster, which happened in July 1988. It was the world’s worst offshore disaster in terms of lives lost and industry impact. It happened because the condensate pump under maintenance was started up with a safety valve removed and recovered by a blind flange. The condensate leaked out and caught fire, resulting in explosions, and oil and gas fires. The incident caused 167 fatalities. Meanwhile, the Texas City Refinery Explosion which happened in March 2005, was caused by a blowdown stack liquid overflow. Hydrocarbon vapour cloud ignited and exploded, and the ignition source was a running vehicle truck. The incident caused 15 fatalities.

The last example he provided was the Deepwater Horizon Oil Spill, which happened in April 2010 and was the world’s largest oil spill in the history of the petroleum industry. The concrete used to seal a well 5,600m below sea level was weak, and resulted in a surge of natural gas that broke through the concrete. The blowout preventer valve failed to close. The methane gas, which expanded into drilling riser to the drilling rig, ignited and exploded. Total fatalities were 11, and oil leakage amounted to 4.9 million barrels, which impacted 68,000 square miles of ocean.

From the cases he mentioned, Ir Chan outlined the process safety management in the development of a petrochemical plant. He explained that process safety management begins from the project development stage, which involved outlining the conceptual design and basic design. These design concepts comprise a selection of feedstocks, process safety information, safety philosophy, layout, segregation of products or feedstocks. The detail design stage included loss prevention philosophy, and hazard and operability study, while the construction stage looked into matters such as quality assurance, quality check, and construction safety. The last stage mentioned by Ir Chan was the operation stage. It included commissioning, operations, maintenance and plant revamp.

He also elucidated that the plant maintenance stage involved application and adherence to live plant safe work procedures; operations and maintenance procedures or practices; job safety analysis; Lock Out Tag Out procedures; permit to work procedure; inert entry procedures; asset inspection and integrity; and emergency response procedures.

“It is very important to instil a process safety culture in the workplace. Management and staff must have a clear understanding of the system and its safety features. This includes providing information on the hazards of highly hazardous chemicals in the process, information pertaining to the technology of the process as well as the information on the process equipment,” said Ir Chan.

He emphasised, “The company must have a positive attitude towards safety measures and incorporate an incentive system that encourages safety in operations. Contractors and service providers are an integral part of process safety management for their client’s facility. When any one fails to fulfil the duty, layers of protection are weakened and the risk of a major incident escalates. Engineering and construction and other service providers can and must create a strong process safety culture. Importantly, instil a chronic sense of unease. Failure is not an option.”

The talk ended with an interactive Q&A session and a group photograph.

© 2019 UNIVERSITI TUNKU ABDUL RAHMAN DU012(A).

Wholly owned by UTAR Education Foundation Co. No. 578227-M LEGAL STATEMENT TERM OF USAGE PRIVACY NOTICE