UTAR’s

Unovate Centre

Start-up incubatee,

Kon10Innovation,

is helping COVID-19 frontliners by creating 3D-printed face shields for

additional protection. These 3D-printed face shields are the ingenious work

of innovative four UTAR Engineering students who have set-up a small

start-up and contributed their time and creativity to support the healthcare

frontliners. Kon10Innovation is a registered enterprise with Lim Kai

Wen as its leader and founder. The other team members consist of Lee Kong

Chian Faculty of Engineering and Science students Lim Tyng Xian, Sin Chia

Ling and Ooi Hsin Yein.

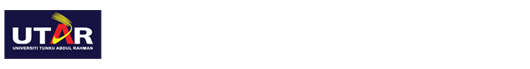

Lim modelling the

3D-printed COVID-19 face shield

Kon10Innovation team members felt

that they needed to do something for all the dedicated medical staff and

enforcement officers who were out there battling COVID-19. “We thought maybe

we can contribute to help the community by providing simpler designs with

shorter printing time and more adaptations to accommodate the sponge feature

on the face shield after watching a Facebook post from the Malaysian

community group who started the 3D-printed face shield,” said the team

members.

The team has also been receiving

feedback from multiple users and health practitioners. Lim said, “The

challenge was to make simple designs while reducing the production time.

Aside from that, there were alterations made to meet users’ feedback and to

accommodate the aspect of comfort and safety. In a day, we can produce

approximately 150 pieces of 3D-printed face shield. It takes 22 minutes to

print and less than 30 seconds to assemble the face shield. Currently, the

face shields are distributed to Klinik Kesihatan, Hospital Kuala Kubu Bharu,

Manipal Hospital Klang and others.”

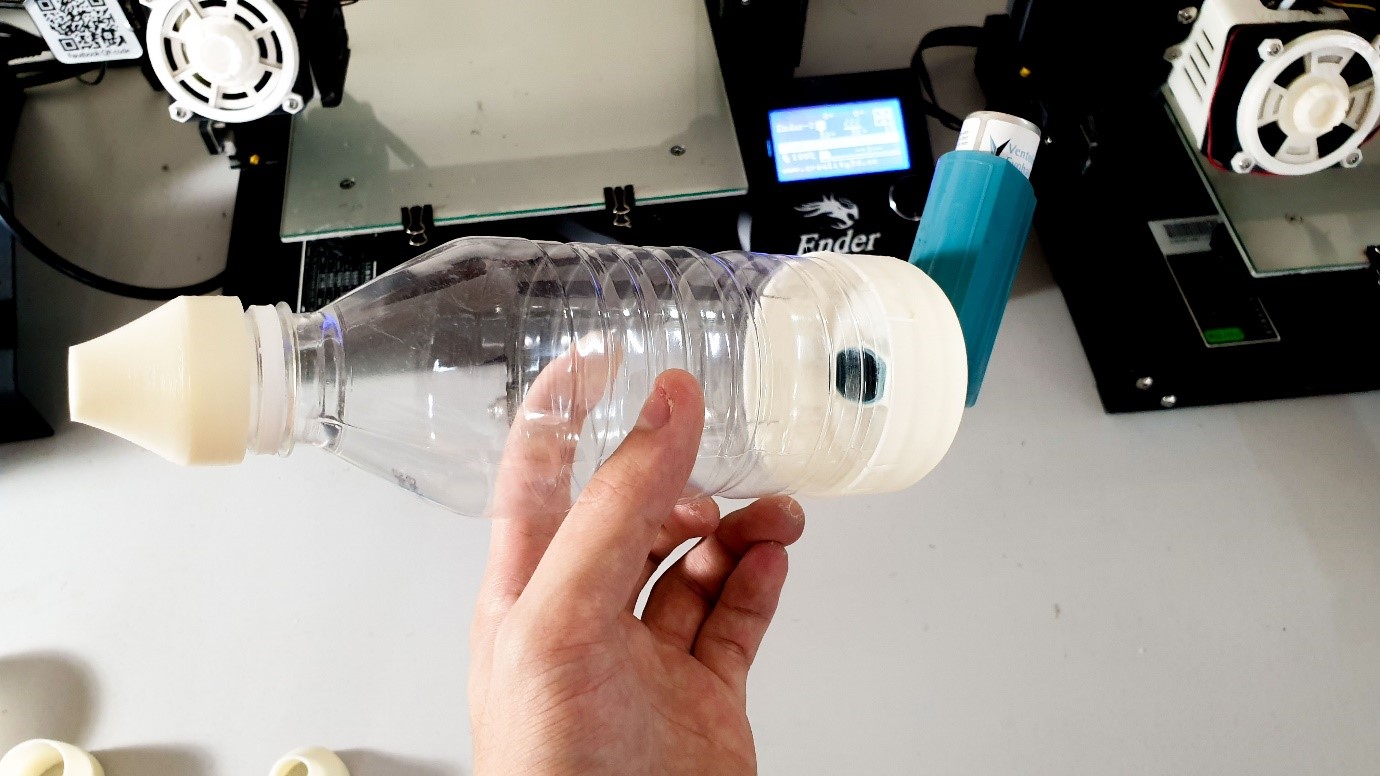

Beside creating 3D-printed face

shields, Kon10Innovation took another step further by creating a nebuliser

spacer.

The team members realised that hospitals

were using bottles with cut-ends as a temporary alternative due to the

shortage of equipment, hence they created a nebuliser spacer using three

3D-printed parts which include a 0.2mm 3D-printed film and a bottle bought

from the local mart.

Nebuliser spacer

“Through some studies, we found

out that most COVID-19 patients are affected by lung inflammation. An

anti-inflammatory drug called salbutamol is used to reduce the inflammations

in the lungs; a small amount is sprayed for the patients to inhale. During

this process, the drug often gets trapped in the patient’s throat and

bronchus, therefore only a minimal amount of drug reaches the lungs.

Therefore, a nebuliser spacer is used to contain and space out the drug with

a proper mixture of air to allow patients to intake the air-mixed drug

properly. Additionally, a valve is used to ensure that the drug travels one

way to avoid backflow when the patient coughs,” said Lim.

Lim added, “There are industries

who have volunteered to sponsor in terms of fabrication of moulds to

accommodate plastic injection by using polycarbonate. With this access, we

will be able to produce roughly 6,000 – 8,000 units which can be distributed

nationwide. Our face shield designs are also in the stage of implementing

plastic injection to accommodate hundreds to thousands of production rate

per day.”

“I think Malaysians should think

out of the box and use any kind of knowledge they may have to help out with

the current situation. We believe that technologies such as 3D printing and

open-source programming are easily accessible by the society and we should

utilise them to provide more ideas and solutions,” enthused Lim.

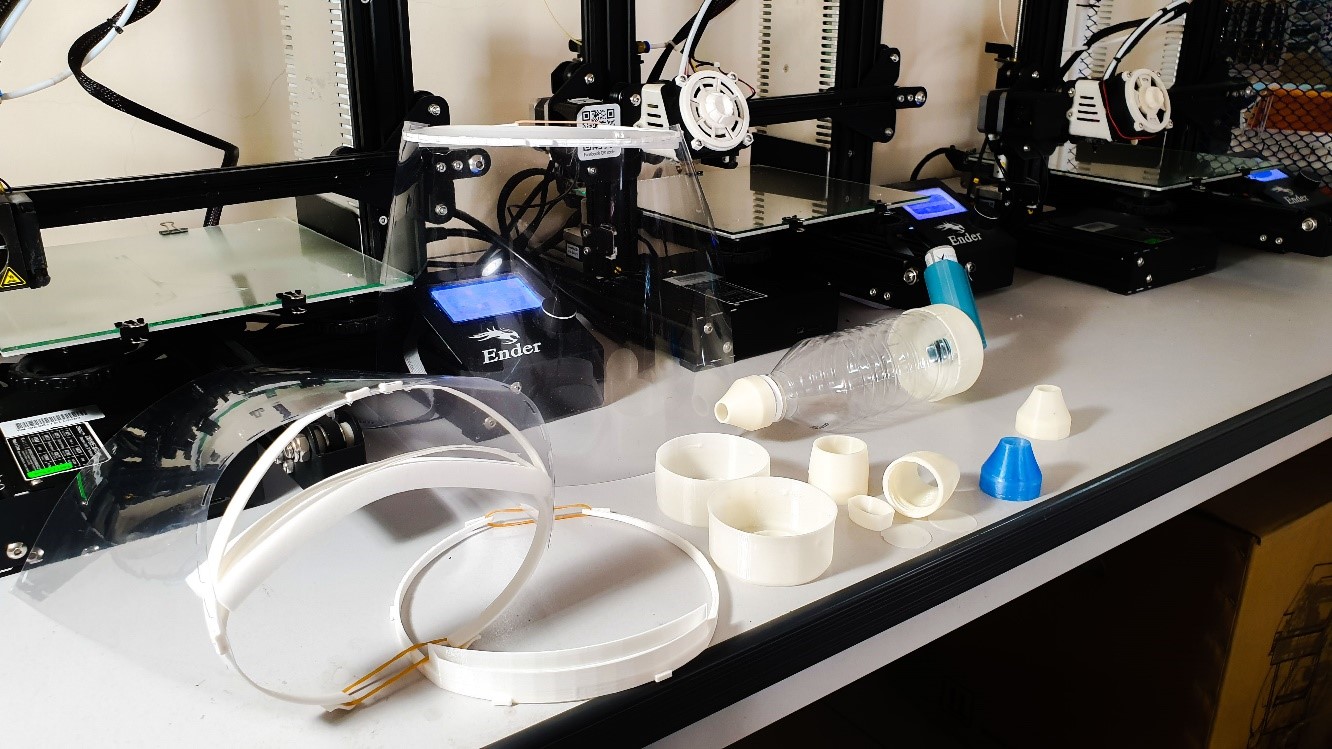

The final products

printed using 3D printers

Besides giving importance on

acquiring information and knowledge, UTAR also focuses on developing

UTARians who are creative, dynamic, practical and effective in wealth

creation. Thus, Unovate Centre was created to foster an entrepreneurial

culture in the campus and also to nurture and accelerate the successful

development of young businesses or start-ups during their early years.

Kon10Innovation is an innovative

start-up company, formed by a group of students from various fields, namely

mechatronics engineering, product designing and programming. Kon10Innovation

provides engineering solution and prototyping services to start-ups and

entry-level industries. They also provide industrial automation design and

precision scale modelling services. Kon10Innovation aims to design human

integrated robotics in the future for the medical field, construction and

logistics. Some of Kon10Innovation’s clients are BoomGrow, Daikin, GogoKids

and more.

Kon10Innovation founding members (from left): students Lim Kai Wen, Lim Tyng Xian, Sin Chia Ling and Ooi Hsin Yein

The 3-D printed face shield

Wholly owned by UTAR Education Foundation Co. No. 578227-M LEGAL STATEMENT TERM OF USAGE PRIVACY NOTICE