As part of the e-KLESF 2021 event, an online workshop titled “An introduction to Cold-Process Soap Making Workshop” was organised on 26 October 2021 via Zoom and Facebook Live.

UTAR Centre for Foundation Studies of Sungai Long Campus Senior Lecturer Ts Amelia Chiang Kar Mun was invited to teach participants the process of producing soap from scratch using the cold-process method. Some lessons on chemistry were taught over the session to teach participants the basics of saponification; the safety in handling lye; how to produce natural colours in soap; how to use a soap calculator; what are the different types of oils used as well as the purposes they serve.

From left: UTAR Centre for Corporate and Community Development Head of Corporate and Community Training Mohd Faizul bin Ahmad (moderator) and Amelia Chiang

“We use soap every single day. Soap is a chemical compound that is very commonly used in our society. We use soap to clean ourselves which is very important, especially during this pandemic. We also use soap to wash our dishes and clothes, to name a few. So it is important to know what soap is made of,” said Amelia Chiang.

Amelia Chiang

She then explained how soaps are made with a chemical reaction called “saponification”. It is a chemical reaction between fats/oils and sodium hydroxide (lye) which is an important element in the soap-making process. “Interestingly, we use soap to cleanse grease and oils from our skin, but soap is made from grease and oils. So this shows that even though the soap is made of oil, it can also remove oil at the same time. It is due to the hydrophilic and hydrophobic properties found in the soap,” said Amelia Chiang.

Explaining the cold process, she said, “Cold process uses the internal heat that is naturally produced during saponification. The bars will completely harden in four to six weeks. Saponification happens over the next 24 to 48 hours. So after we do the cold process, it actually hardens pretty fast. However, the whole process still takes about one to two days. As for the curing process, we still need to take four to six weeks because it contains NaOH (the chemical formula of sodium hydroxide). We don’t want our soap to be too alkaline. It is not good for our skin, the best pH value for soap is 5.5. Moreover, I choose the cold process because it gives us more flexibility to do swirls and embed designs within the soap batter before pouring it into the mould. Cold process soap batter is much thinner when it is poured into the mould, and the mould is usually insulated. Soap made through the cold process method will look more shiny and polished compared to hot process soap. ”

She continued, “However, the disadvantage of cold process soap is that once it is poured into the mould, it takes about 24 to 48 hours for the saponification process to occur. The soap is then removed from the mould, sliced into bars and cured for four to six weeks. The longer the curing time, the harder the bar as the water/liquid within the soap has the opportunity to evaporate.” She then moved on to explain the structure of the soap and the saponification process.

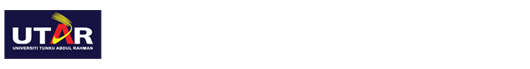

According to Amelia Chiang, lye is a key ingredient in the production of soap. Through a chemical reaction, it converts oils and fats to what we know as soap. Lye is usually found in drain openers because it can clear clogs by converting greasy buildups into something that can be rinsed away. It has a strong base and is corrosive. It can burn, blind and kill someone if ingested. Hence, it should be handled with care and be labelled.

Safety precautions to consider when working with Lye

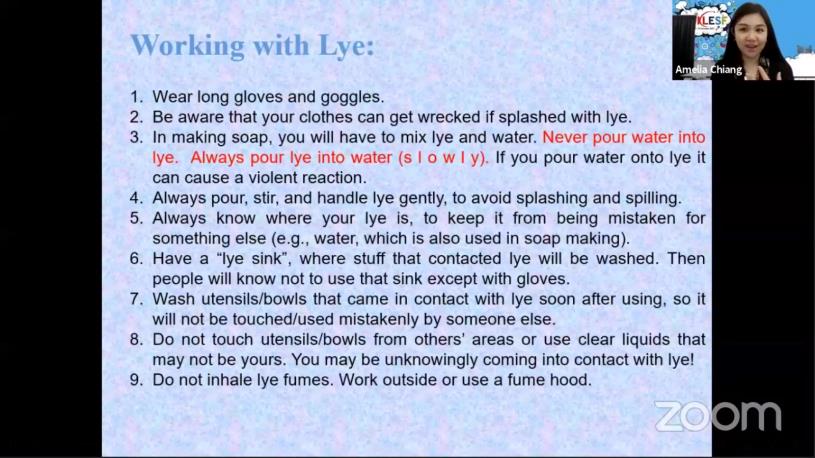

Different fats or oils produce different qualities of soap

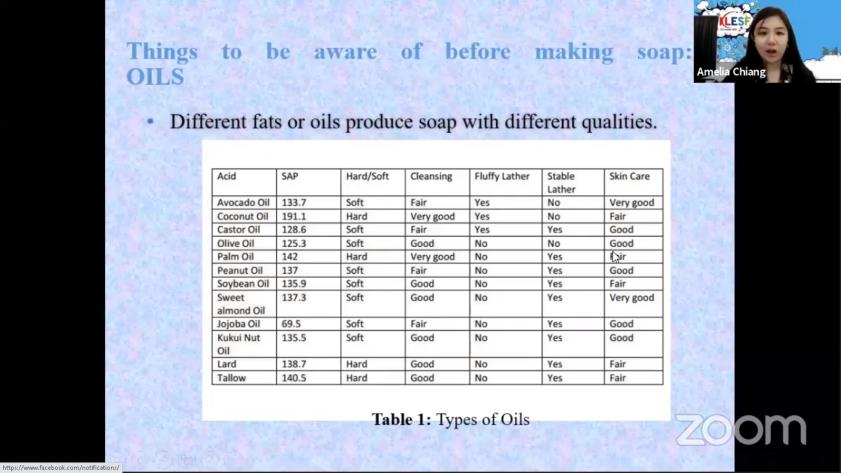

Trace

Ingredients and apparatus needed to make soap

The procedures

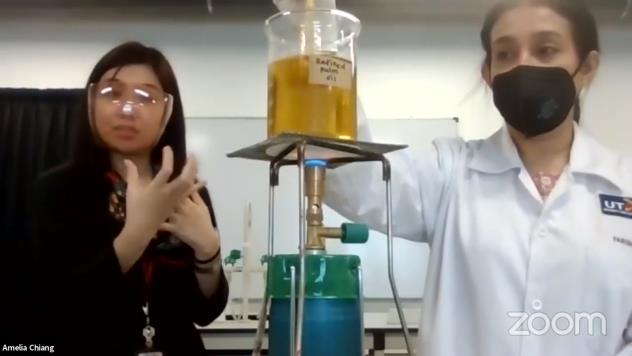

Amelia Chiang and CFS (Sungai Long Campus) Assistant Laboratory Manager Wan Nur Farisha binti Wan Mohd Tajuddin demonstrating how to make cold-process soap

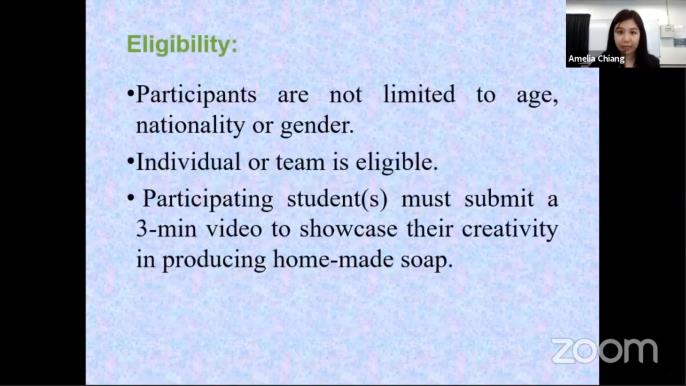

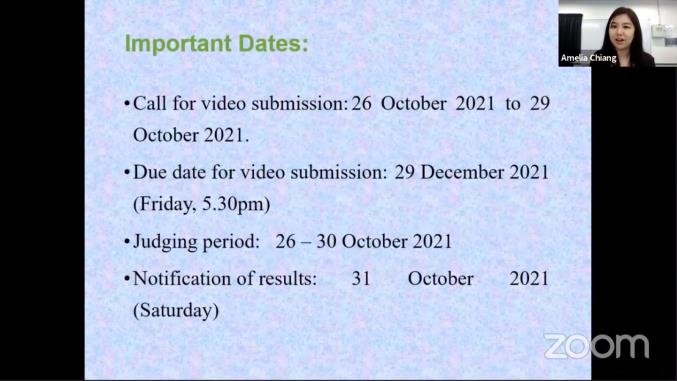

To encourage hands-on activity, a “3-Min Video Competition: Producing Home-made Soap” was held to motivate the participants to showcase their creativity in producing homemade soap. The winner will be announced on the last day of e-KLESF on 31 October 2021 during the e-Award ceremony.

A group photo session to end the interesting workshop

For more information about the competition, please click here.

Click here to watch the full webinar.

© 2021 UNIVERSITI TUNKU ABDUL RAHMAN DU012(A).

Wholly owned by UTAR Education Foundation (200201010564(578227-M)) LEGAL STATEMENT TERM OF USAGE PRIVACY NOTICE