Aiming to build awareness on the importance of trust along the food supply chain, UTAR Centre for Agriculture and Food Research (CAFR) and Faculty of Science (FSc) collaborated with Chiayi University and Food Consultants for UTAR Community Project for Food Industries Lam Ah Chye and Lai Mun Lee to organise a three-day webinar titled “Building Trust Along the Food Supply Chain” on 4, 8 and 11 November 2022 via Zoom.

With the generous support from the sponsors, Nestlé (Malaysia) Berhad, Sai Kim Enterprise Sdn Bhd, and Kawan Food Bhd, UTAR invited 10 speakers from a wide array of food disciplines to share their professional experience and knowledge in regard to building trust along the food supply chain with the public. The webinar attracted over 130, 150, and 90 participants on the respective days.

For years, FSc has provided UTAR staff, students and the public with professional knowledge while discussing a variety of topics and issues regarding food science. In 2021, a three-day webinar was organised to discuss the significance of sustainable food packaging in capturing the hearts of customers. This year, FSc rolled out yet another insightful three-day webinar which discussed the beguiling relationship between trust and food supply chain.

The webinar began with FSc Dean Assoc Prof Dr Lim Tuck Meng thanking the organising committee for their enthusiasm in organising the meaningful webinar. He also said, “For the past two years, our daily activities have been disrupted by the restrictions imposed on our movements due to the Covid-19 pandemic. The supplies necessary to our life, particularly food, have been affected due to planning issues and manpower shortages. I believe this webinar will reduce some of the issues related to food supply. This could also enlighten us on practical issues which have affected the running of this industry.”

In her remarks, CAFR Chairperson Dr Tan Yen Nee said, “We have come to the fifth year of organising such a meaningful event with continuous support from various parties to bring knowledge of food science and safety to the community, especially the food industry. A reliable and trustworthy supply chain is a prerequisite for success which brings about the theme of this webinar ‘Building Trust Along the Food Supply Chain’.”

Dr Tan expressing her sincere gratitude for the continuous support from FSc

Lam, who is also the founder of AC Lam Enterprise, shared his take on trust in a food supply chain. “If we search on Google, there are many definitions of trust. In the context of this webinar, it is all about the ability to deliver quality in the midst of vulnerability. Trust is essential to forming and reinforcing long-term relationships with consumers. It enables brands to deliver better experiences, increase loyalty and retain more consumers. Brand trust can be the vital differentiation for consumers to choose your brand over another company,” said Lam.

Lam sharing his thought on the concept of trust in food supply chain

Session 1

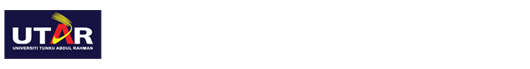

The first speaker for session 1 was Kawan Food Berhad Director Dr Nik Ismail bin Nik Daud. He shared his wisdom regarding customer’s trust in his topic titled “Building trust to win customers”. “Trust plays a huge part in creating the foundations of a successful business. It does not only lead to a business’ growth, but it also makes customers less price sensitive. This is very important, especially now, since the production costs are rising,” clarified Dr Nik Ismail. There are undeniably various challenges in building trust. As examples, he showed some ways that companies practice to build trust. One of them is a small company named “Flavor Inn”. Regardless of the monopoly by big companies in the food flavouring industry, Flavor Inn sustains itself by displaying its professional expertise and procedures to the customers by employing food flavouring specialists and equipping itself with proper and necessary equipment, thus boosting confidence level and trust among customers. Dr Nik Ismail also enlightened the participants on some factors to consider when building customers’ trust in food companies. They included primary laws and standards of the land; market listing requirements for listed companies; the company’s trustworthiness, and specific customer requirements. Companies may put endless effort into building customers’ trust, nevertheless, their works have to be audited as proof to the public. One common way to verify the efforts is by writing an annual report which thoroughly includes not only a company’s mission and vision, but also its business direction and performance. Ending his talk, Dr Nik Ismail said, “Customers trust a foundation to a successful business, but trust among customers takes time to develop, once damaged, it is hard to repair.”

Dr Nik Ismail elucidating the building blocks that contribute to customer’s trust

The second speaker, National Ocean University of Keelung Academic Prof Hsiao, Hsin-I, shared her knowledge on the topic “The association of circular agriculture with sustainable food supply chain”. To present the topic with depth, she presented her research on the exploration of oyster shell waste in green packaging. It was shown to the participants that oyster shells were being increasingly reused as an assortment of items such as medicine, cosmetics, farmyard manure, feed ingredients and seedling cultivation medium due to some regulations set by the authorities. However, much to the participants’ surprise, oyster shells contain antimicrobial properties which can benefit food preservation. In conjunction with degradable Poly Lactic Acid (PLA) film, Prof Hsiao and her team set out to discover the efficacy of their performance in fish fillet preservation. They combined oyster shell powder with PLA to develop three generations of unique films. Each generation contained varying concentrations and particle sizes of oyster shell powder. In their endeavour, they found that the PLA-oyster shell powder films with higher concentration of oyster shell powder were effective in preserving the fish fillets. Expressing her thought on the preservation potential of the developed film in other food sectors, Prof Hsiao said, “There are still many uncertainties yet many possibilities to explore. One of the sectors which I think is interesting is the vegetables and fruits sector because supermarket uses a lot of plastic bags to pack them. This sector might just be our next testing ground as it can help in reducing plastic bags which is one of the prevalent causes of pollution.”

Prof Hsiao sharing her enthusiasm towards the packaging’s effectiveness with the participants

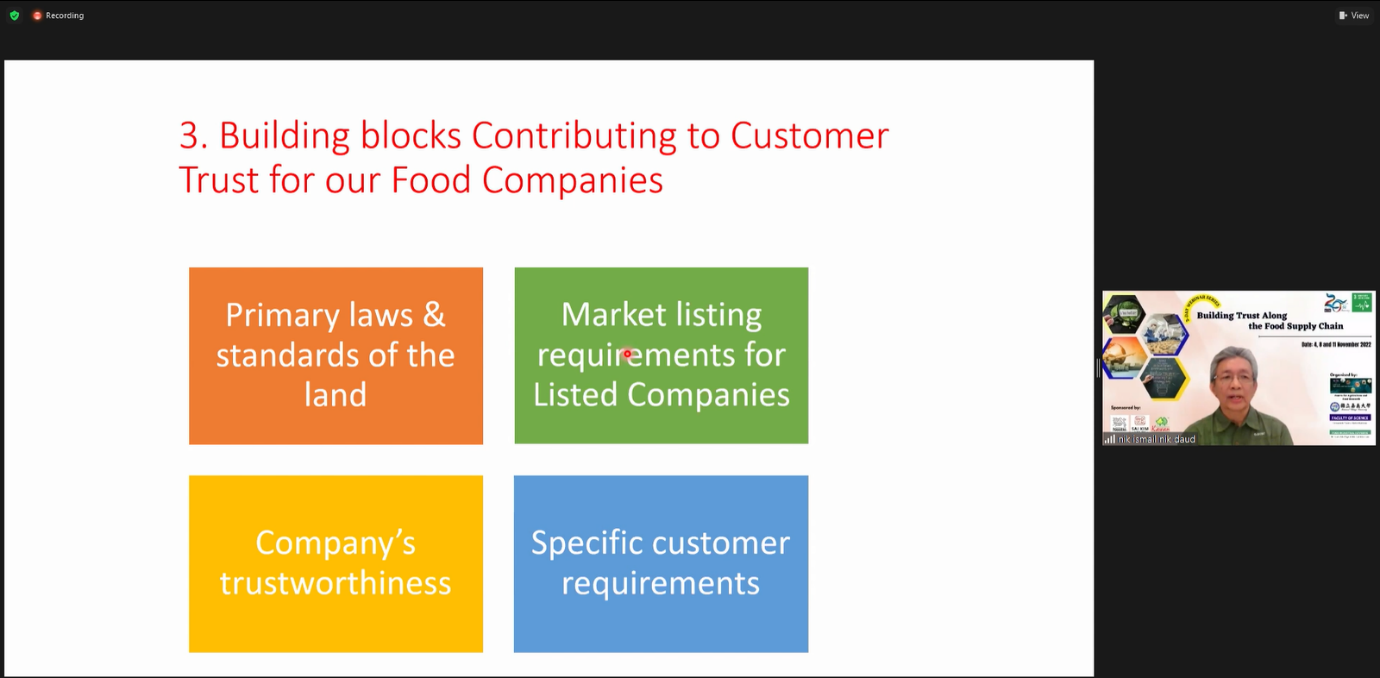

The third and final speaker in session 1 was the Manager of Southeast Asia of DNV Business Assurance Singapore Pte Ltd Food and Beverage, Rachel Ng. In her topic titled “Food safety and quality assurance along the food supply chain”, Rachel Ng enlightened the participants on the technical aspects of the Food Safety Management System (FSMS). FSMS is a programme that aims to prevent food safety hazards that might cause adverse health effects on consumers. There are various FSMS, some of them are Hazard Analysis Critical Control Point (HACCP), International Organisation for Standardisation (ISO 22000) and Food Safety System Certification (FSSC 22000). Among them, FSSC 22000 is recognised by the Global Food Safety Initiative (GFSI) which is considered to be a scheme that set the highest standards globally. Nonetheless, Rachel Ng explained that different FSMS have varying scopes of business. For example, the food trading business and pest control business for the food industry are not covered in FSSC 22000, but they are applicable in ISO22000. To be eligible to apply for FSMS, a food-related business must fulfil a set of technical requirements, but the requirements are different in accordance with the FSMS. Overall, FSMS provides many benefits to a business not only in business growth, but also build trust in customers by controlling food hazards and meeting customers’ requirements.

Rachel Ng diving into the technical details of ISO 22000

Session 2

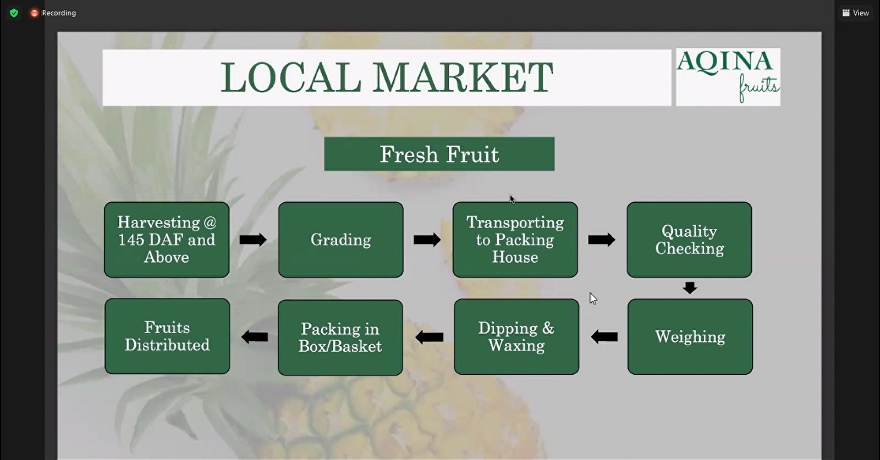

As for session 2, the first speaker was the Group Executive Director of Aqina Fruits Sdn Bhd, Wesley Tan Seah Ging. He shared his experience in managing the transportation of fresh pineapples from the farm to the end consumers. In Aqina Fruits Sdn Bhd, the harvesting of pineapples takes place 145 days after flowering (DAF) as a method to control the planting and harvesting process. As an example, Wesley Tan gave a scenario when the demands for pineapples surge during the Chinese New Year. He said, “We have to plan ahead of these coming 145 days and start flowering the pineapples in order to get the right amount. This way, we control their shelf life, thus reducing wastages.” With harvesting completed, the pineapples have to be graded and later dipped in organic fungicide and waxed with fruit wax to ensure chemical-free preservation. The ways of distribution for the local market and oversea market varies in the packaging process, storage process and distribution channel. For fresh-cut pineapples in the local market, Aqina Sdn Bhd uses a unique packaging called modified atmosphere packaging (MAP) that changes the gaseous atmosphere in the packaging to inhibit microbial activity. The distribution process in the local market is done within a day to ensure the freshest quality. However, exporting requires a long time because the harvesting process takes effect earlier by usually 10 days and sea freight is used as the cost-efficient shipping method. Taking into consideration the distance of countries from Malaysia, it may take from seven to 20 days to arrive at a designated market. Wesley Tan also advised, “We really need to understand the supply chain and demands from customers as proper planning can reduce wastages. We also need to work on technology and management as well as work with all the players in a supply chain to deliver the freshest produce to consumers.”

Wesley Tan showing the flow of processing pineapples at his company

The second speaker, the President of the Society of Logisticians, Malaysia, Prof Ts Chang Kah Loon, imparted his knowledge on reefer shipments to the participants with his topic “Refrigerated shipping management for perishable goods”. Introducing the reefer container, Prof Chang said, “It should not be viewed as a fridge, since it is a refrigerated container that only preserves the products temporarily by maintaining a low temperature with a temperature cooling system installed on the container.” With the notion conveyed, he listed out the steps involved in a reefer supply chain. Multiple parties are involved in the process, including the freight forwarder, shipping line, container depot, container hauler and port terminal. Efficient cooperation between the parties is required to ensure a smooth process. The container stuffing and vessel loading have to be done within one or two days due to the container’s unstable temperature during the stuffing process. Prof Chang emphasised that multiple temperature inspections of a container are essential for products’ preservation status before and after the stuffing process. Only when the container is at the port that the responsibility of the container’s check-up falls to the container depot. Moreover, he explained the limitations faced by reefer containers, specifically the limitation of the container inventory; limitation of slot allocation for reefer containers on a ship; low frequency of reefer shipment due to its special requirement; high cost of maintenance; extra coordination effort due to its temperature inspections during the shipment process; and lastly the disputes arising from spoiled and damaged products.

Prof Chang presenting some trivia and fun facts about reefer container

The third speaker, Ecolab International Sdn Bhd Technical Support Manager, Wong Hwee Jiau, shared the process involved in cleaning factory equipment in his topic titled “Food factory cleaning and sanitation”. Before diving into the main topic, Wong presented the latest food safety trend to the participants. It is stated that the globalisation of food trade has brought greater emphasis but a more complex process on food safety. The demand for healthier and “safer” food skyrockets yet food hazard cases become more visible to the general public. Wong reaffirmed the participants that food safety has a big leap forward, rather the improved detection of food hazards has kept the general public well-informed on the issues. He viewed this as good news from the public health standpoint as further improvements can be made to allow better food safety. In terms of equipment sanitation, Wong elucidated the four main steps in cleaning and sanitation process of factory equipment which include pre-rinse, cleaning, rinsing and disinfection process. The first step, pre-rinse, primarily removes 95% to 98% of visible soil from the equipment. The second step, cleaning, is where most of the microorganisms and soil are removed. The cleaners must choose the right chemical; understand the mechanical action of the equipment; the most efficient temperature for the chemical; and the contact duration of the soil in the equipment to produce the best result. Once done, it will be rinsed with water to remove 99% of the soil in the equipment. The final step, disinfection, is implemented to ensure the level of microorganisms is reduced to 0.001%. Nonetheless, a sterilisation process is needed for some sensitive products to completely eliminate microorganisms. “Food safety is not about cleaning and sanitation alone. You need a holistic approach to relook at the entire process and the supply chain. It can help understand the challenges and how to prevent them,” said Wong, before ending his topic.

Wong assuring the participants of the modern and improved food safety protocol

The fourth and final speaker for session 2 was the Head of HALAL Affairs of Nestlé Malaysia, Nestlé Manufacturing (Malaysia) Sdn Bhd, Othman bin Md Yusoff. With his decades of experience in managing Halal affairs both internationally and domestically, he shared the story of his humble beginning from being a technician to becoming one of the most experienced Halal affairs managers in Malaysia. In 1994, he and his team from Nestlé synced their effort with the imams of the Islamic Centre, Malaysia to establish Malaysia Halal Certification for food products. Malaysia was the first to officially publish a guideline for Halal certification and the guideline has since been the touchstone for many countries around the world. There were many Halal business opportunities since the 2000s due to the surging demand for Halal-certified products. One of them was the introduction of “Halal SuperHighway”. It is a supply chain meant to serve as a gateway for Halal to reach Europe with its Halal logistics; nevertheless, it ultimately did not materialise due to the high cost of alienating Halal products from non-Halal products. Regardless, Othman viewed it as a fascinating idea. In addition, he clarified that the risk of Halal non-compliance mainly revolves around the materials used in products. Due to this issue, he deemed the traceability of a product as utmost significance when shipping a Halal product. Being constantly aware of the product’s whereabouts in the supply chain can significantly lower the risk of cross-contamination between Halal and non-Halal products. He even mentioned that Halal food products alone made up for about 1trillion US dollars of world income. “Halal business is lucrative yet a very sensitive one. You cannot afford to make mistake. You have to be well-aware and diligent to make sure things are in checks all the time,” commented Othman, as advice for participants who wish to step into Halal business.

Othman explaining some fascinating Halal concepts proposed by European and Asian countries

Session 3

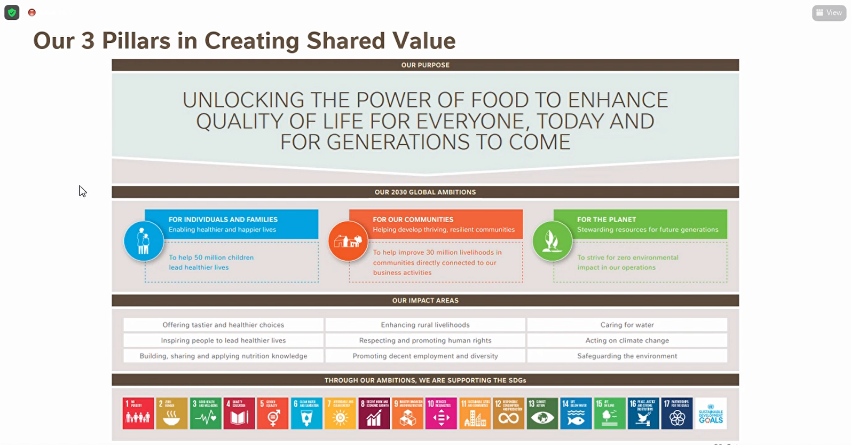

In session 3, the first speaker, Nestlé Products Sdn Bhd Head of Sustainability and Government Relations Michelle Woon, enlightened the participants on the philosophy Nestlé is employing to create value for all the shareholders and ultimately lead to trust building among them in her topic titled “ESG compliance in driving sustainability”. In her remarks, Michelle Woon said, “Speaking of building trust, over the years, we can see a shift in the capital market, from focusing on maximising the returns of shareholders to maximising the values of shareholders.” To elaborate on ESG compliance, she showed the comprehensive value chain of Nestlé, in which the multinational conglomerate corporation works with parties along the supply chain such as farmers, logistics providers and consumers to reduce carbon footprint and improve the production process. By advocating sustainability, not only does the corporation shape customers’ offerings, but they also lead end consumers to make sustainable purchases and consumptions. Michelle Woon commented, “We also need action from governments and regulators to create clear and fair rules for companies to make progress on ESG compliance.” Other than that, Nestlé’s three pillars in creating shared value were also presented to the participants. They strive to create value for every shareholder through the enhancement of food sustainability by collaborating with various parties in the supply chain. The programmes shown were Nestlé for Healthier Kids (N4HK), MILO sports programmes, Project Releaf, and MILO Sayang Bumi, to name a few. With incessant efforts in promoting sustainability, it proves to the suppliers and customers that Nestlé cares for the well-being of the environment and people, hence improving their image in harnessing environmental cooperation which ultimately leads to trust building in their supply chain.

Michelle Woon clarifying the purpose of Nestlé’s three pillars in creating shared value

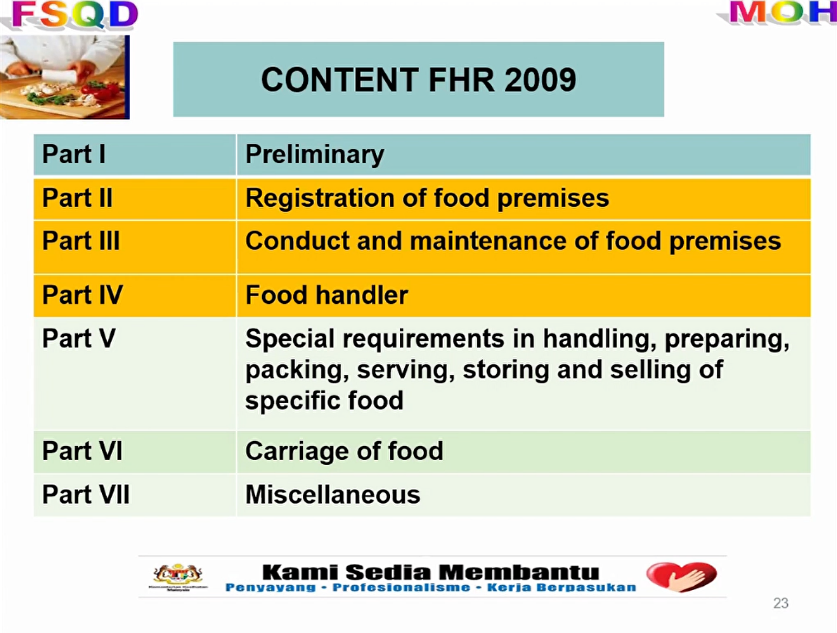

The second speaker, Food Technologist for Food Safety and Quality Department of Perak State Health Department, Sunmuglvadivu Elumalai, spoke about the rules and regulations involved in food and beverage (F&B) establishments in her topic titled “Hygiene and standards in F&B outlets”. To better understand the relationship between food hygiene and customers’ trust, Sunmuglvadivu clarified that customers lose trust towards an F&B brand mainly due to deteriorating food quality. Not to mention, food hygiene directly affects the quality of the food, hence leading to a chain reaction between trust and food hygiene. An F&B establishment requires audit from national food control systems such as the Malaysia Food Act 1983 and Food Regulations 1985 to declare its hygiene credibility. Another regulation system is the Food Hygiene Regulations 2009. It is considered the most applicable standard for F&B establishments as it facilitates workplace inspection by the Ministry of Health (MoH), Malaysia. Further into the topic, Sunmuglvadivu shared some certification systems currently offered by MoH, Malaysia, including BeSS Certification, Home Based Certification, Trust MyCatering Certification, GMP Certification, and HACCP Certification. Among them, BeSS Certification is considered to be the basic standard for F&B establishments, whereas HACCP (Hazard Analysis Critical Control Point) Certification is considered the highest and most complex standard for F&B establishments in Malaysia. Sunmuglvadivu added, “Establishments which are awarded HACCP Certification will be automatically awarded GMP and also MeSTI certifications for food factories. It is accepted globally. For example, exporting F&B establishments with HACCP certification are able to export to any country in the world.”

Sunmuglvadivu shedding light on the importance of Malaysian food safety legislation

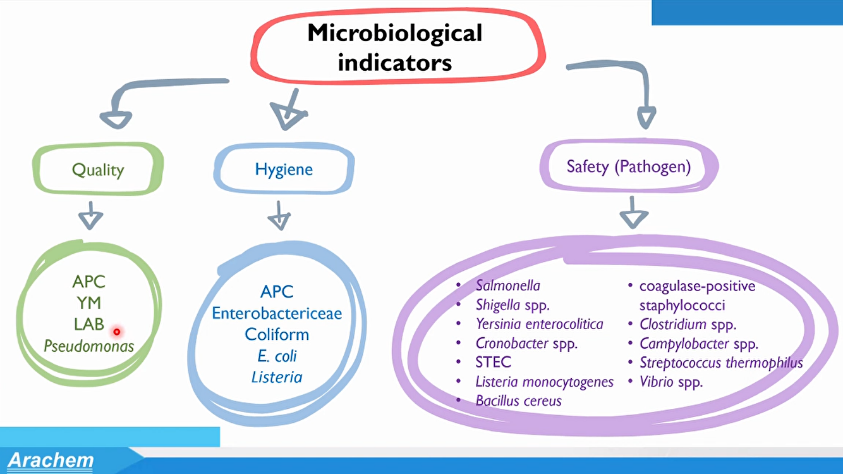

The third and also the final speaker of the webinar was the Senior Manager of Biotechnology Division of Arachem (M) Sdn Bhd, Tee Siang Lyn. In her topic titled “Measuring food quality: Concept, methods, and accuracy”, she introduced the concept of food quality based on two dimensions, which are the customer’s and producer’s points of view. In this context, the customer’s expectations toward a product are subjective while the producer’s expected specifications of a product are objective. Nevertheless, both are essential in shaping the quality of a product. Most of the time, food standards in different countries are unfair mainly due to the diverse standards set by the respective authorities. This is especially true for the F&B trading sector. Tee elucidated a scenario where Malaysian products might not be accepted by Korea due to Korea’s stricter standards, but the latter’s products are accepted in Malaysia, causing inequality. As a countermeasure to this issue, the World Health Organization (WHO) established Codex Alimentarius, non-mandatory international food standards that F&B traders can voluntarily use as international trading standards. Diving into the main topic, Tee introduced microbiological indicators by explaining that they are microorganisms present in the environment which can be utilised by F&B producers to measure the level of food quality, hygiene and safety. For example, one of the common bacteria, E Coli, is used prominently to test the level of food hygiene, yet it is not suitable to test food safety and quality. The indicators are used prominently due to their rapid and frugal efficiency. Some methods used nowadays, including conventional culture-based methods, film methods, enzyme-substrate methods and lateral flow methods were also shown by Tee before concluding her session.

Tee revealing the types of microorganisms used as indicators in different areas

As the webinar reached its conclusion, Food Consultant for UTAR Community Project for Food Industries Lai Mun Lee, who is also a trainer of ShinRyu Consultancy, advised, “To stay active and competitive in today’s business, one must be able to build quality and safety consistency. Building trust derives from building quality and food safety culture across the supply chain.”

Lai sharing her outlook on the relationship between trust and food supply chain

Dr Tan Yen Nee seized the moment to express her heartfelt appreciation to the speakers and moderators for their professional conduct. She added, “Developing a reputation for quality has been important to the food sector and yet challenging. Certification schemes have proven an important way that food makers can foster trust in their products. Traceability is also the key to securing food supply. For the benefit of all, all of us, the food industry, academia, the authorities, and even the service providers can be involved together to uplift the food safety and hygiene standards in our communities.”

The three-day webinar ended with a virtual group photography.

Dr Tan (top row, far left), Universiti Sains Malaysia academic Dr Tan Thuan Chew (second from left), Lai (fourth from left), Lam (second row, centre), Dr Lim (third row, far left) and Tee (fourth row, far left) with the organising committee and participants

© 2022 UNIVERSITI TUNKU ABDUL RAHMAN DU012(A).

Wholly owned by UTAR Education Foundation (200201010564(578227-M)) LEGAL STATEMENT TERM OF USAGE PRIVACY NOTICE