Remedial practical class on industrial hygiene and safety

Faculty of Engineering and Green Technology academic Dr Lim Fang Lee conducted a special practical class on “Industrial Hygiene and Safety” on 30 November 2022 at UTAR Kampar Campus.

The class was attended by Bachelor of Science (Honours) Environmental, Occupational Safety and Health students. It provided practical lessons on human vibration and heat exposure, using equipment specially rented from Universiti Putra Malaysia (UPM) for a period of two days.

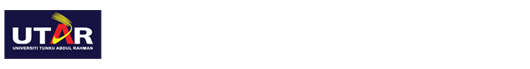

Dr Lim explaining HVM to students

The Human Vibration Meter (HVM) is used to test vibration on a worker’s whole body or hand arm. Dr Lim explained, “We are exposed to various sources of vibration in our daily life. Excessive level and long-term exposure to vibration can deteriorate our health, especially workers who are exposed to vibrations daily, such as when driving buses and tractors or using some powered hand tools. Human vibration meter is usually used to measure hand-arm vibration and whole-body vibration in order to calculate their daily exposure value normalised to an eight-hour reference period.”

She added, “This is important to ensure the workers are exposed to daily vibration level that is under the exposure limit value (ELV) to prevent the development of hand-arm vibration and whole-body vibration syndrome (vascular disorders that are characterised with low blood circulation in the fingers or muscle). Thus, this remedial practical class aims to expose the students to the measurement techniques and results interpretation which are beneficial in their future career as a safety and health officer or industrial hygienist.”

She then demonstrated the methods for conducting the vibration test. The test consists of a human vibration meter, a seat accelerometer used for the whole-body vibration test and a few types of accelerometer adaptors used for the hand-arm vibration test. Each test, including data collection, requires about 10 to 20 minutes to complete.

Students testing the hand-arm vibration when operating a hand-powered tool

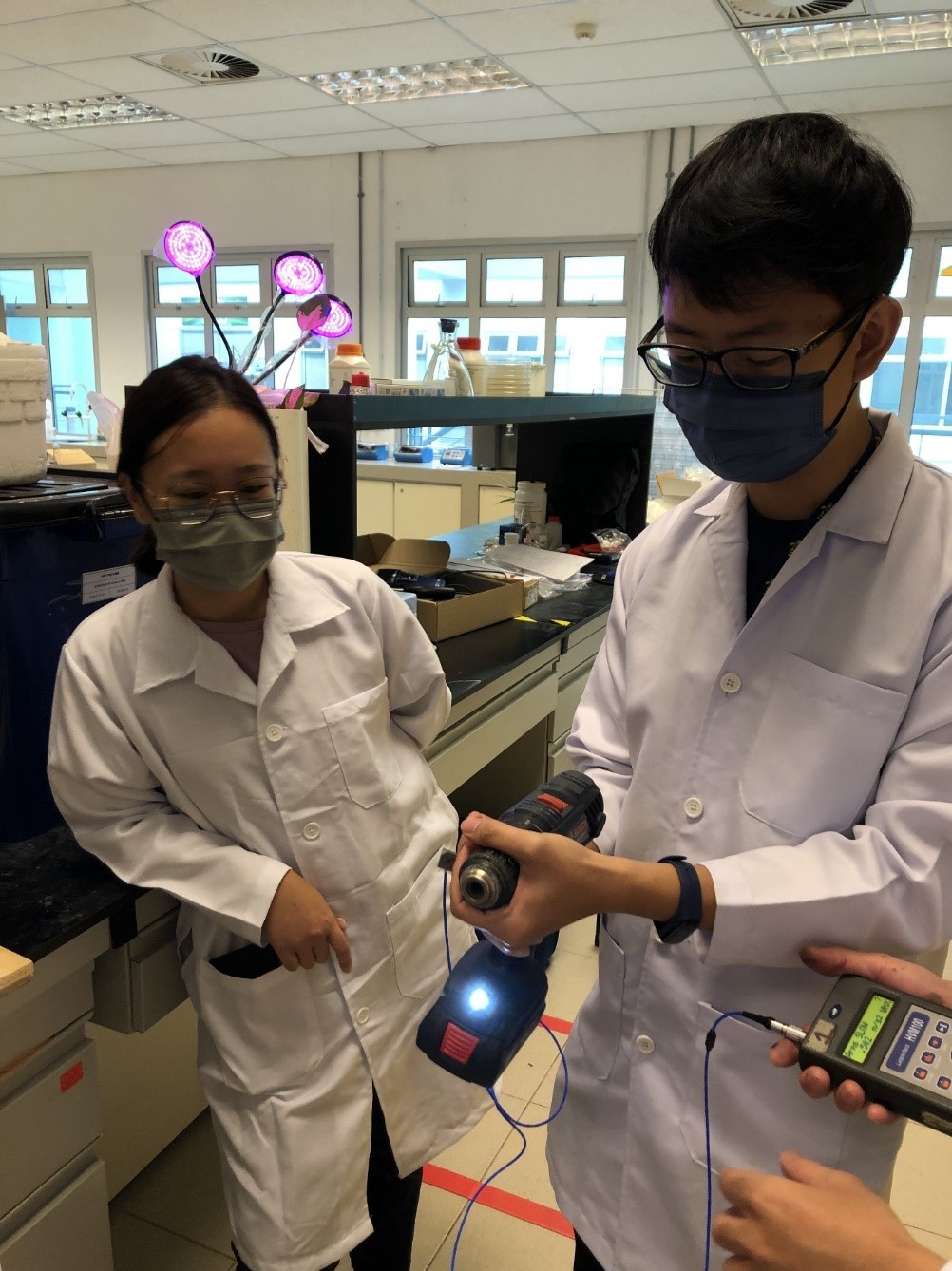

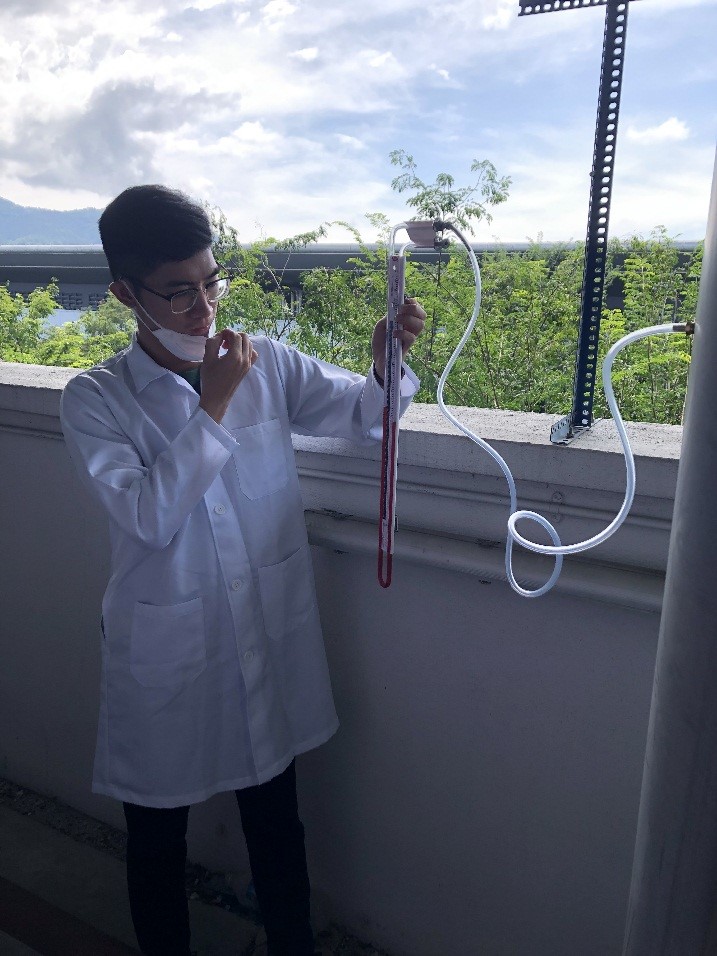

Dr Lim explaining the use of the WBGT

Meanwhile, the Wet Bulb Globe Temperature (WBGT) is the equipment used to test heat stress exposure among workers. The equipment, with its sensors sitting on three levels from varying heights of 0.1, 1.1 and 1.7 meters, is meant to measure the various heat exposures of the workers from the ankles, abdomen, and head levels respectively, if the temperature surrounding the worker is not uniform. The test, including data collection, typically takes about 60 minutes to complete.

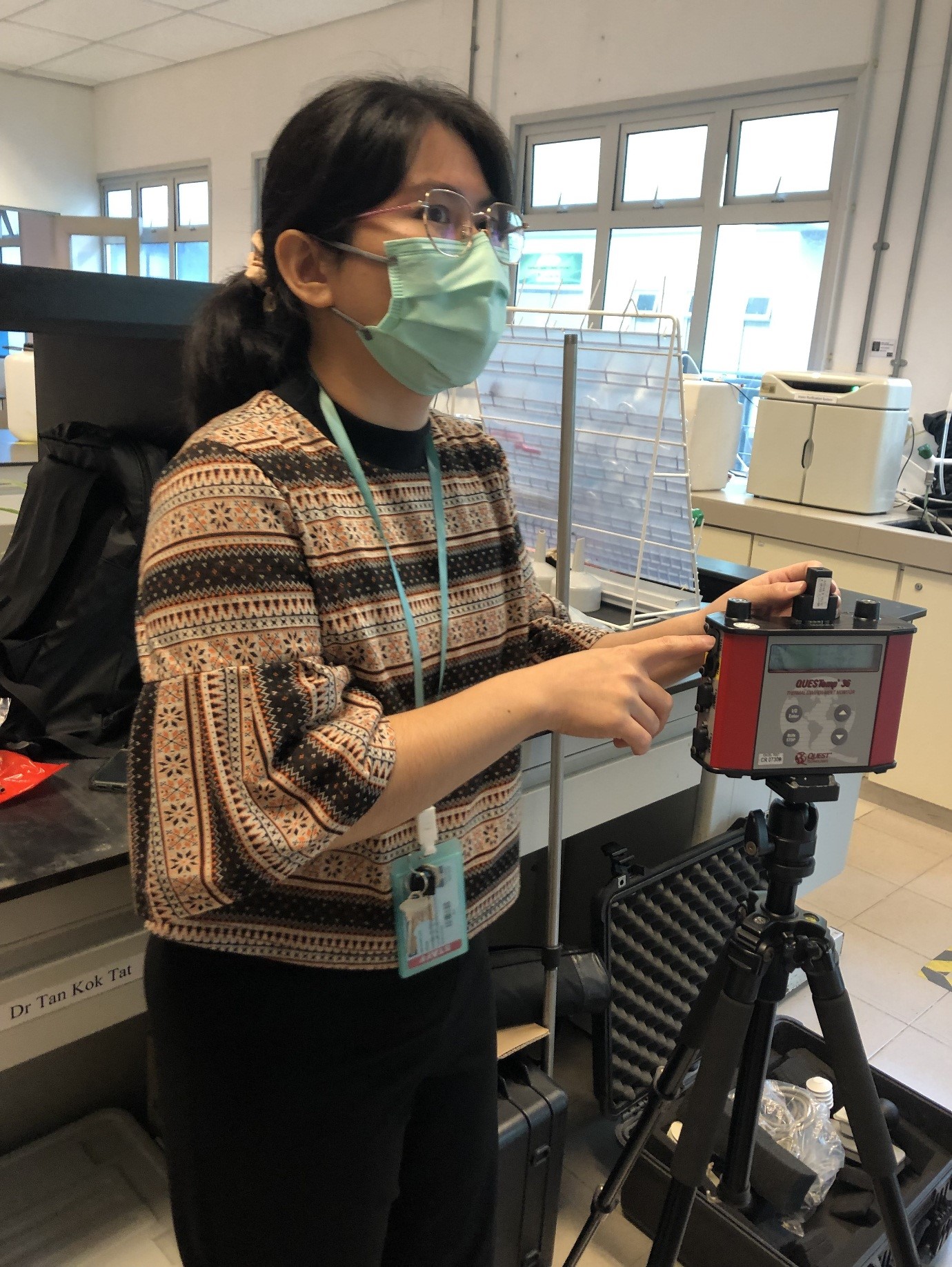

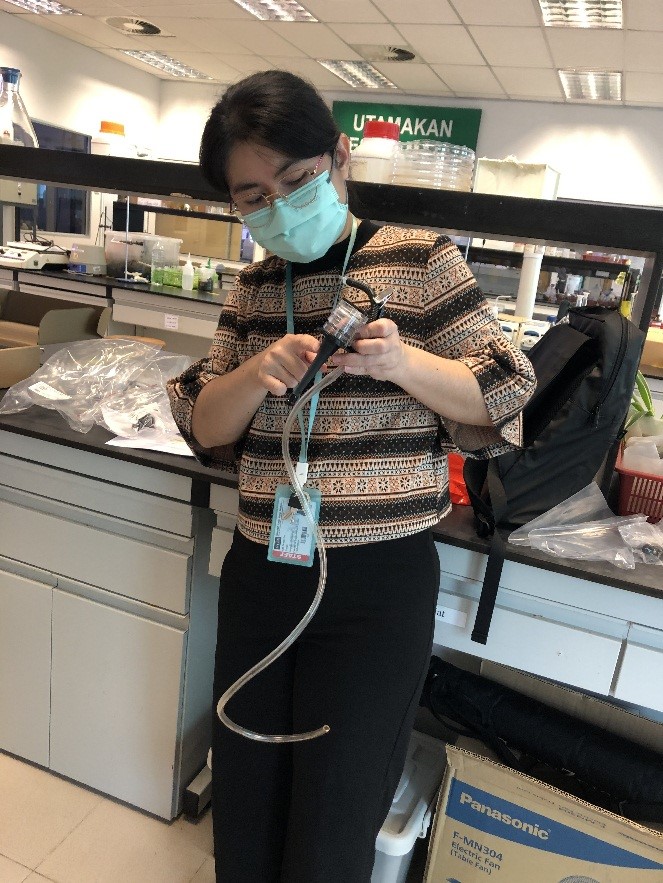

Dr Lim demonstrating the use of a personal air sampling pump

Additionally, Dr Lim also taught the students chemical exposure monitoring using personal air sampling pump connected to the air sampling cassette, which aims to sample the concentration of respirable particulates inhaled by an individual worker at the workplace. The sampling is conducted for eight hours, during a worker’s usual working operations. The charcoal sorbent tube, on the other hand, is used to monitor the concentration of organic vapours and gases in the air, inhaled by the worker.

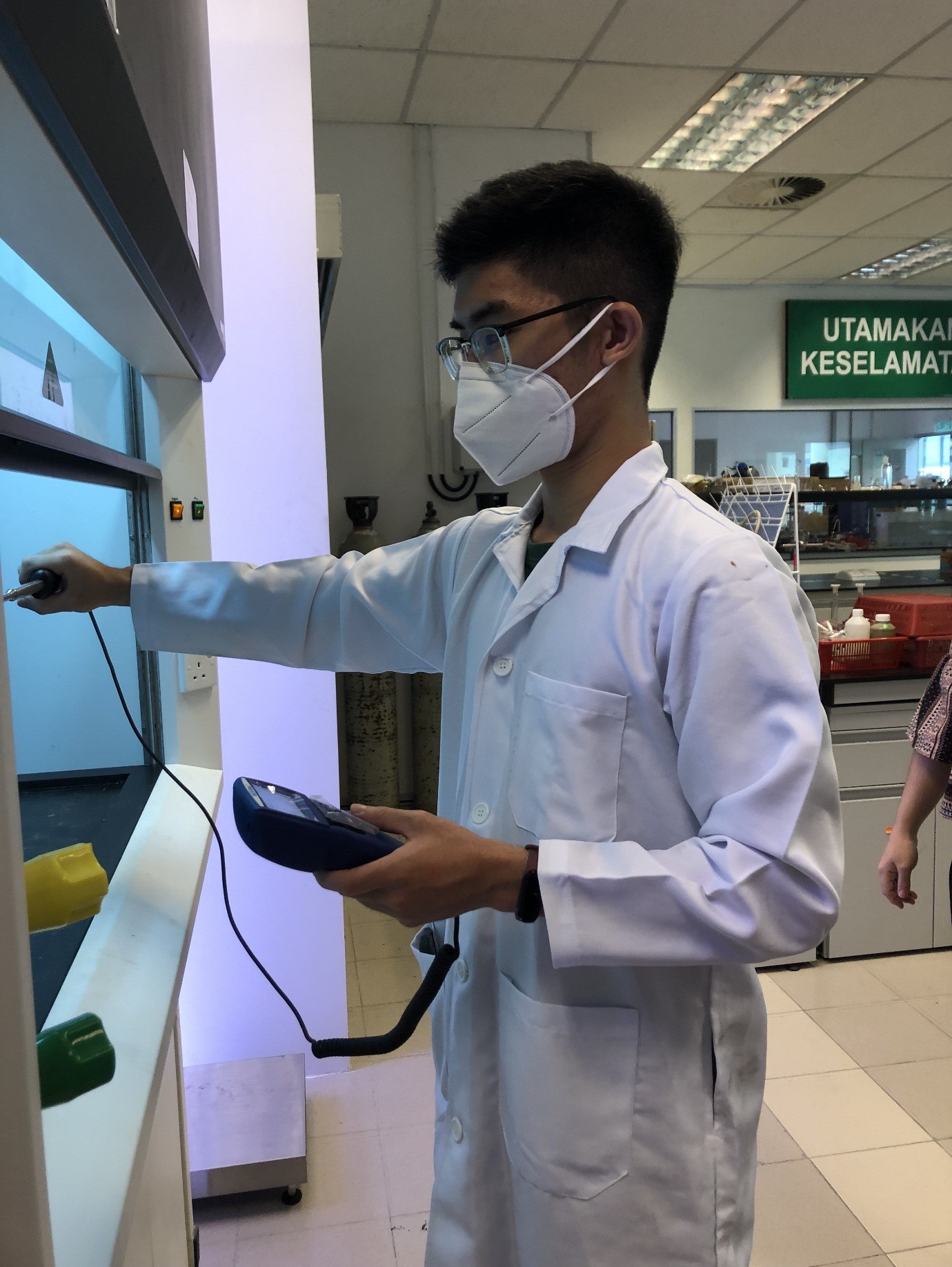

The student testing the face velocity of the fume hood

Students conducting static pressure measurements at the fan outlet of the LEV system

Dr Lim also demonstrated the fume hood testing to teach students about Local Exhaust Ventilation (LEV) System testing. She explained that the LEV testing and examination is conducted annually by a competent Hygiene Technician 2, who is registered under the Department of Occupational Safety and Health, to ensure the efficiency of the fume hood in ventilating the chemicals so it remains safe for the fume hood users. In this test, different components of the LEV system were inspected. Static pressure and velocity pressure of the dusting system were measured. The static pressure allows the tester to know the resistance to airflow in the ducting system, while the velocity pressure measures the pressure produced by the airflow in the ducting system.

© 2022 UNIVERSITI TUNKU ABDUL RAHMAN DU012(A).

Wholly owned by UTAR Education Foundation (200201010564(578227-M)) LEGAL STATEMENT TERM OF USAGE PRIVACY NOTICE