Top row, from left: Prof Rajeshwar and Prof Bashir with UTAR staff and students

UTAR Faculty of Engineering and Green Technology (FEGT) and Division of Community and International Networking (DCInterNet) jointly organised a webinar titled “Understanding bioplastic materials – current state and trends” on 9 February 2023 via Zoom. It saw more than 100 participants in attendance.

The webinar, moderated by FEGT Head of Department of Environmental Engineering Prof Dr Mohammed J. K. Bashir, aimed to enlighten participants about the manufacturing processes and current trends of bioplastic.

The invited speaker was Prof Rajeshwar D. Tyagi, a professor of Institut National de la Recherche Scientifique, Canada, and a visiting professor of Hong Kong Baptist University and Canada Research Chair in Bioconversion of Waste Water and Sewage Sludge into High-Value-Added Products. Prof Rajeshwar’s research mainly focuses on reducing and turning waste into value-added products. In recognition of his outstanding contribution to the advancement of science and technology in environmental biotechnology, Prof Rajeshwar had received several awards, including the American Academy of Environmental Engineers and Scientists’ (AAEES) Superior Achievement Award; International Bioprocessing Association’s (IBA) ASCE State-of-the-Art of Civil Engineering Award and Outstanding Scientist Award; International Water Association’s (IWA) Global Honour Award for Applied Research, and 2016 Mahatma Gandhi Pravasi Samman Award.

Prof Rajeshwar giving a brief introduction to bioplastic

Prof Rajeshwar gave a brief explanation of the differences between conventional plastic and its biodegradable counterpart, bioplastic. “Plastics have become part of our daily life due to their high usability. In 2020, global plastic production reached 367 million metric tons. However, the mass production of petroleum plastics has caused significant deterioration in both environment and animal health due to its toxic properties. As the world grew more aware of the environment, people shifted their focus from producing petroleum plastics to bioplastics. Though, bioplastic is still not commercially viable in mass production because of various factors,” shared Prof Rajeshwar when introducing the subject. He further explained that petroleum plastics will become microplastics even after they break down. They will continue to pollute the environment and ultimately animal and human health.

On the other hand, bioplastic uses bio-based materials that are renewable, microbe-degradable and non-harmful towards the environment. The most common materials of bioplastic are poly-lactate and polyhydroxyalkanoates (PHAs). Moreover, Prof Rajeshwar explained the structures, characteristics and production capacity of PHAs plastics. PHAs can be extracted from some agri-food-based and ligno-cellulose-based products such as wheat and rice straw, wood, sugar cane juice, banana and potato peels, soybean, starch, corn, and rice. “Unfortunately, bioplastics are not cost-competitive compared to petroleum plastics. Their production cost is high due to the high cost of raw materials and complex manufacturing process,” explained Prof Rajeshwar.

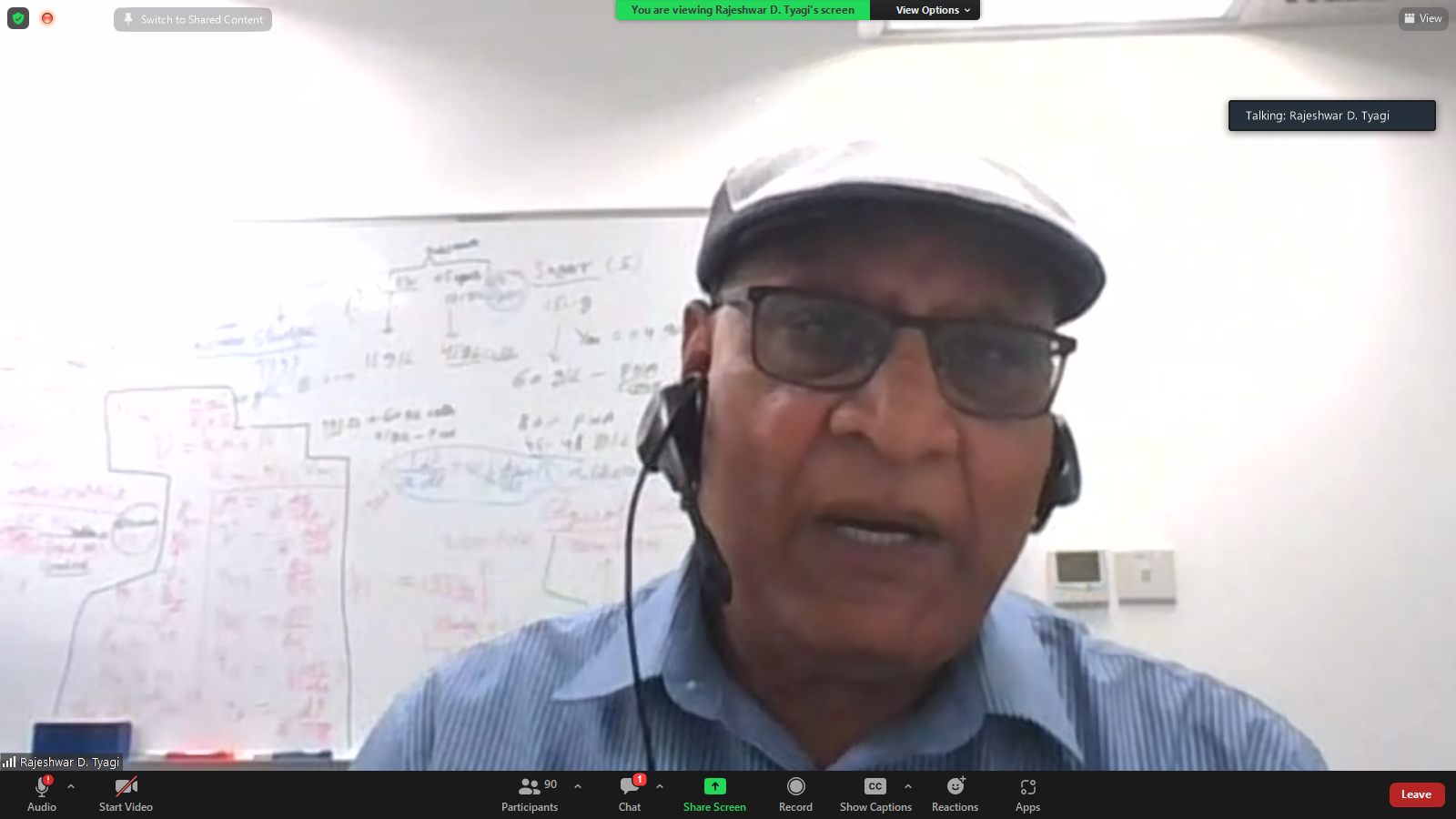

Prof Rajeshwar elucidating the production process of bioplastic

Aside from extracting PHAs from organic waste, Prof Rajeshwar stated that PHAs could also be obtained from sludge, a semi-solid waste by-product obtained during wastewater treatment. Since sludge contains an abundance of PHA-producing microbes, it can be fermented and purified to produce PHAs. They can either be processed through mixed or pure culture. Prof Rajeshwar said that mixed culture tends to have lower production costs but at the same time lower PHAs output compared to pure culture. Other than that, he also shared some factors affecting PHAs production, including substrate ratio, microbial community, temperature, suspended solids, fermentation techniques and scale-up issues.

The webinar ended with an interactive Q&A session and a group photography session.

© 2023 UNIVERSITI TUNKU ABDUL RAHMAN DU012(A).

Wholly owned by UTAR Education Foundation (200201010564(578227-M)) LEGAL STATEMENT TERM OF USAGE PRIVACY NOTICE